High temperature Airslide fabric

- Description

- Inquiry

INTRODUCTION

We provide Airslide belt for conveying bulk material by air gravity. The main use of Airslide belt is discharging, declining transportation or homogenizing the powder or small granular material in quiescent condition. Our airslide belt is named as Airslide fabric, Airslide membrane, Air slide cloth, Air slide canvas, Air permeable fabric, and Fluidization cloth, fluidising fabric, etc by our customer. We adopt 100% polyester for airslide fabric material.

HIGH TEMPERATURE AIRSLIDE FABRIC

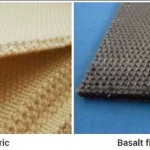

High temperature Airslide fabric is Nomex, Kevlar, Baslt material Airslide fabric

PRODUCT CLASSIFICATION

Our POLYESTER fabrics can be used at temperatures between -60°C and +150°C. The airslide fabrics are made from polyester yarns.

We also have the Nomex, and basalt material, which can suitable for 240 and 450 degree temperature.

ADVANTAGES

- High temperature resistance: It can remain stable in high temperature environments and is not easy to deform or melt.

- Good air permeability: Gas and moisture can pass freely to prevent heat accumulation and moisture problems.

- Wear resistance and corrosion resistance: It has good wear resistance and corrosion resistance and a long service life.

- Clear and smooth texture: Stable size and not easy to deform

WORKING PRINCIPLE

An Airslide belt is in the middle of a chute. Powder material will come into the chute above Airslide belt. Material will flow to the chute lower side as pneumatic blower down Airslide belt. That’s why we say Airslide belt can move powder material because of the wind power. And then, the rest wind will go out from the top of the chute. Through the moving, no parts moved except powder material. So that it can spare more energy and maintain cost, etc.

Our Airslide canvas is installed on the surface of the silo bottom. It is supplied for installation as aeration units on the sloped conical bottoms of bins and silos to aid in the withdrawal of dry relatively free-flowing material.

SPECIFICATION DATA

Airslide fabric ( Basalt 6-350)

- Raw Material =100% basalt fiber

- Weight in average = 4000 g/m2

- Thickness = 6 mm

- Mean Air Permeability = 400 m3/m2h @350H2O Breaking Strength => 5000N/4cm2

- Breaking Elongation =<3%

- Max Width: 2000mm

- Operating Temperature < 450 deg.C Recommended Maximum Continues <750 deg.C Recommended Maximum Surge = 750 deg.C

Airslide fabric ( Kavlar 6-350)

- Raw Material =100% Kavlar fiber

- Weight in average = 4200 g/m2

- Thickness = 6 mm

- Mean Air Permeability = 400 m3/m2h @350H2O Breaking Strength => 1000kg/10mm2

- Breaking Elongation =<5%

- Max Width: 2000mm

- Operating Temperature < 220 deg.C Recommended Maximum Continues <240 deg.C Recommended Maximum Surge = 240 deg.C

Airslide fabric ( Nomex 6-350)

- Raw Material =100% Nomex fiber

- Weight in average = 4000 g/m2

- Thickness = 6 mm

- Mean Air Permeability = 400 m3/m2h @350H2O Breaking Strength => 550kg/10mm2

- Breaking Elongation =<5%

- Max Width: 2200mm

- Operating Temperature < 220 deg.C Recommended Maximum Continues <240 deg.C Recommended Maximum Surge = 240 deg.C

PACKING