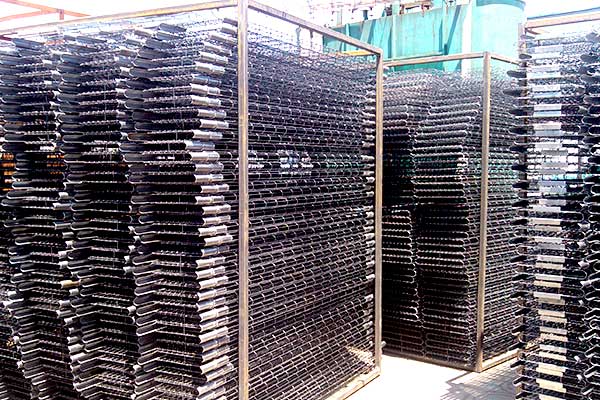

Filter cages

To support filter bag in baghouse, filter cage will keep the filter bag in open state. To facilitate the passage of gas and the barrier of dust.

- Description

- Inquiry

INTRODUCTION

As the support of filter bag in the process of use, the skeleton has important use significance

MANUFACTURING

Manufacturing process of dust removal frame : Wire drawing, ring welding, straightening welding, spraying, curing

Wire drawing and ring welding: First, the thick steel wire is drawn into the required diameter of steel wire, such as 3.2mm, 3.5mm, 4mm, etc. through the wire drawing process. Then, the steel wire is wound into a ring using mechanical equipment and welded into shape with a welding machine.

Straightening and bag cage body welding: The wire after wire drawing is straightened by a straightening machine and welded with the previously made steel ring to form a bag cage body. This step ensures the straightness and strength of the bag cage.

Welding head cover and bottom cover: The welded bag cage body is connected with the purchased head cover and bottom cover through a welding process to complete the overall welding of the bag cage.

Surface treatment: After welding, the dust removal frame will be surface treated, including silicone spraying, galvanizing or electrostatic spraying. Silicone spraying is to spray evenly on the surface of the skeleton automatically or manually, and then bake and cure to ensure that the silicone is firmly attached to the skeleton.

Material and use of dust removal skeleton: The dust removal skeleton is usually made of Q235 material, and the surface treatment can be galvanized or silicone. It is an important part of the bag filter, which plays a role in supporting the filter bag and ensuring the normal operation and filtering effect of the filter bag.

VARIOUS KINDS OF FILTER CAGES

The types of dust removal frames mainly include the following:

Ordinary dust removal frame: It adopts a circular or polygonal design, with a simple manufacturing process and a wide range of applications, but the filtration area is relatively small.

Keel-type dust removal frame: It is composed of multiple parallel keels and panels, which can increase the filtration area and is suitable for large dust removal equipment, but the manufacturing process is more complicated and the maintenance cost is higher.

Trapezoidal dust removal frame: It adopts a trapezoidal design, which can increase the filtration area and improve the filtration efficiency, but the manufacturing cost is higher.

Spring-type frame: It is suitable for replacing filter bags in the wind head.

Fence-type filter bag frame: It is welded with 6-12 diameter 4mm, 10# steel wires, and the surface is smooth and burr-free.

Hole-type frame: It is made of 2.5-3mm copper-plated steel plate waste with a pore size of 20mm. After use, the filter bag has a longer life, but the effective filter bag area is reduced.

Flat bag frame: It is generally an external filter, and there are two types: spring type and steel wire type.

AFTER TREATMENT OF FILTER CAGE

Since the dust collector frame is welded, some parts are not very smooth after welding, which can easily scratch the bag. Therefore, the dust collector frame needs to be sprayed on the surface. The main treatment methods are:

Galvanized: has good rust resistance and is suitable for humid or corrosive environments.

Plastic spraying: The surface is sprayed with a plastic layer, which has good corrosion resistance and aesthetics.

Organic silicone treatment: Improve the high temperature resistance of the frame and is suitable for high temperature environments.