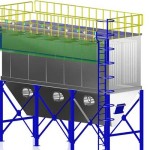

Chamber type dust collector

Cleaning filter bags one chamber in together.

Advantages:

1. Avoid excessive blowing filter bag.

2. Offline cleaning bags avoid dust blowing & come back.

3. Filter bags cleaning speed fast.

4. 1500g / m3 dust content is available

- Description

- Inquiry

Introduction

The chamber type long bag dust collector is to clean the surface of the cloth bag in the box room after closing the separate box room. After closing the chamber, the chamber is in a state of 0 pressure, which overcomes the disadvantage of cleaning while filtering, and the filtering air pressure and the pulse cleaning pressure reduce each other. When the length of the filter bag is less than 2500mm, only 1-2 pulse valves can be installed in each chamber for spraying, and the cloth bags in the entire chamber can be cleaned. Save energy. This is the large industrial dust collector.

Main product parameters

Air volume of dusty gas: up to 120000m3/h

Filter area: up to 1280 m2

Suitable dust air temperature: up to 280 degree

Dust concentration in output: up to 3mg / m3 ( due to the dust collector setting)

The chamber type long bag dust collector is to clean the surface of the cloth bag in the box room after closing the separate box room. After closing the chamber, the chamber is in a state of 0 pressure, which overcomes the disadvantage of cleaning while filtering, and the filtering air pressure and the pulse cleaning pressure reduce each other. When the length of the filter bag is less than 2500mm, only 1-2 pulse valves can be installed in each chamber for spraying, and the cloth bags in the entire chamber can be cleaned. Save energy. This is the large industrial dust collector.

ADVANTAGE

The chamber type dust collector is a dust collector developed on the basis of the stand-alone type dust collector.

- It is to overcome the shortcomings of the single-unit dust collector that while collecting dust while cleaning the filter bag, the suction air pressure of dust collection and the blowing pressure of the bag cleaning are offset. The figure on the left is a schematic diagram of pulse injection of a stand-alone dust collector.

2. On the right is a schematic diagram of the pulse injection of the chamber type dust collector. It is to close the air inlet of the box chamber first, then open the pulse valve, and use compressed air to clean the dust filter bag.

3. Chamber type dust collector can process dust with higher dust concentration per unit volume. For example, ordinary stand-alone dust collectors are not recommended to process dusty gas with a dust concentration higher than 100g/m3. The air box dust collector can process dust-containing gas with a dust concentration of 2000g/m3.

STRUCTURE DESCRIPTION

(1) Shell part: including clean room (or gas purification box), filter room, compartment partition, access door and shell structure. The clean room is equipped with a poppet valve, a flower plate, and a short blowing pipe: a filter bag and its skeleton are installed in the filter room.

(2) Ash hopper and ash unloading mechanism: The ash unloading hopper can be equipped with screw conveyor, air conveying chute and rigid impeller discharger (ash unloading valve) according to different series and different imported dust concentrations.

(3) Air inlet and outlet box body: including air inlet and outlet pipes and central partition. The single-row (or single-row) structure is arranged on one side of the shell, and the double-row (or double-row) structure is arranged in the middle of the shell: 32 series are smaller without a box, and the air inlet and outlet pipes are respectively connected to the ash hopper and the clean room .

SPECIFICATION