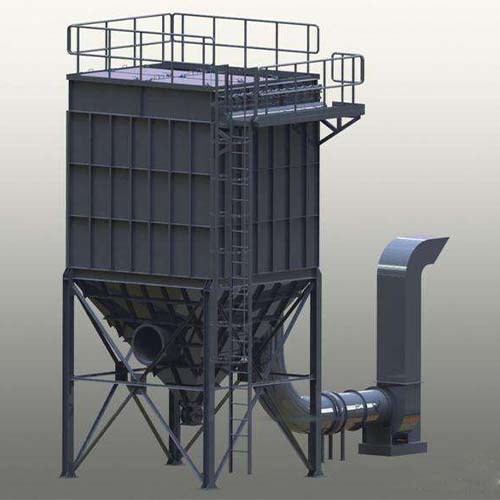

パルスジェットシングルタイプダストコレクター

- 説明

- 問い合わせ

導入

バッグタイプの工業用ダストコレクターはドライフィルターデバイスです. ミキシング空気をクリーン空気と粉塵に分離できます. パルスジェットの吹き付けは、フィルターバッグに空気または窒素をスプレーするために使用されます. パルスジェットの目的は、フィルターバッグの表面に自動的に取り付けられたほこりを除去することです .

バッグタイプの工業用ダストコレクターはドライフィルターデバイスです. ミキシング空気をクリーン空気と粉塵に分離できます. パルスジェットの吹き付けは、フィルターバッグに空気または窒素をスプレーするために使用されます. パルスジェットの目的は、フィルターバッグの表面に自動的に取り付けられたほこりを除去することです .

主な製品パラメーター

ほこりっぽいガスの空気量: まで 54000 m3/h

フィルター領域: まで 600 M2

Gas temperature: まで 280 程度

出力のダスト濃度: 最大3mg / M3 ( more smaller more better)

応用

The picture on the left shows that the dust collector removes dust from the indoor grinding equipment. 加えて, the dust collector can also be used in many occasions. See more application industries here.

例えば: wood processing workshops, furniture factories, coal-fired boiler exhaust emissions, セメント植物, various smelting and dust emission places. It is impossible to list them all, but only the dust removal of grinding equipment as an example.

PROJECT DISPLAY

|  |  |

SERVICE SCOPE

1. Customized design

We will beginning our service upon received your industrial dust collection requirement. According to your detailed requirement, we will design the dust collector to suit for your circumstance.

In another words, for every customer, we will customized the equipment for every different circumstance application.

2. Manufacturing

As usual, according to the detailed dust collection circumstance Analysis, we can assure our equipment building material the mostly suitable (matching) for application. So that, One set of equipment can be used for more than 10 – 20 years. Even more, under good maintenance, It can support for 30 years operation.

|

3. Assembling & test running

4. Painting

4. Painting

Sandblasting is required before painting. Spray paint is three times: 1. metal primer 2. anti-corrosion paint 3.surface coat.

5. Check before shipment

5. Check before shipment

We welcome customers to inspect the quality in person or by entrusting a third party before delivery.

Your valuable opinion is our way forward.

6. Installation guide & site construction

6. Installation guide & site construction

Our service lasts long after you use the equipment normally. During the service life of the equipment, we are responsible for the whole process of after-sales.

SHIPMENT

We can send full set of dust collector into one container

We can send full set of dust collector into one container

フィルターケージ & all spare parts will be packaged well.

PRODUCTION SPECIFICATION

Client

DUTCH ASPHALT MIXING PLANT GUEST

The guest factory equipment was burnt out because of entering sparks. They are urgent need the spark checking device to ensure the safe operation of dust collector. After purchasing our products, the use effect reaches the expected standard.

KNAUF FACTORY ENGINEER COME TO DISCUSS DUST COLLECTOR

The Knauf engineer talked with us about dust collector products. In order to avoid errors in production process, the engineer came from abroad to communicate with us.