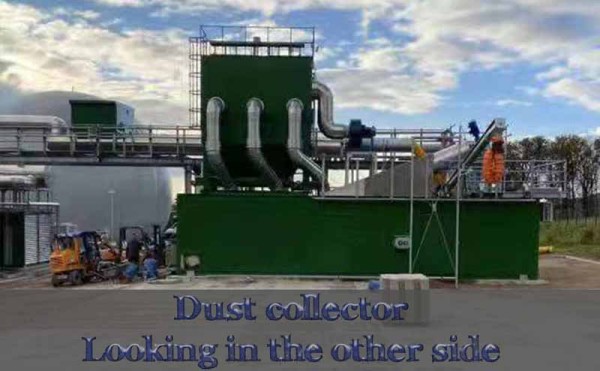

カートリッジダストコレクター

Like the bag filter, the Cartridge dust collector is also a device used to collect and filter industrial dust. Because the surface area of the unit filter cartridge is larger than the filter bag, the filter air volume of the unit filter cartridge dust collector is very large. In the case of relatively low dust concentration, the filter cartridge pulse jet dust collector is more cost-effective.

- 説明

- 問い合わせ

導入

Since the filter material is used in a fold cylindrical shape, the density of the filter material is large. したがって, compared with the bag filter, the volume of the filter cartridge filter with the same air volume is much smaller;

主な製品パラメーター

ほこりっぽいガスの空気量: up to 200,000m3/h

フィルター領域: まで 3600 M2

適切なダスト気温: まで 130 程度

出力のダスト濃度: 最大3mg / M3 ( ダストコレクターの設定により)

応用

Due to the limitation of the machine width of the folded filter material, the maximum length of the filter cartridge is 2400mm, which cannot be made 6 meters long or 8 meters long like a cloth bag. The corresponding features are easy installation and small maintenance workload;

プロジェクトの紹介

1. Mechanical processing industry: Plasma, laser cutting and welding processes in industries such as automobile manufacturing, shipbuilding, and large steel structures will generate a large amount of metal dust, welding smoke, 等. Cartridge dust collectors can effectively collect and process these dusts, purify the workshop air, protect the health of workers, and prevent dust from damaging equipment.

2. Chemical industry: In the chemical production process, various chemical dusts, particles and other pollutants will be generated. Cartridge dust collectors can efficiently filter these fine dusts to prevent dust from being discharged into the environment and causing pollution, meeting environmental protection requirements.

3. Food processing industry: In the process of flour processing and feed production, a large amount of food powder will be generated. Cartridge dust collectors can collect and process these food powders to ensure the cleanliness of the production environment, and recycle these powders to reduce production costs.

3. Food processing industry: In the process of flour processing and feed production, a large amount of food powder will be generated. Cartridge dust collectors can collect and process these food powders to ensure the cleanliness of the production environment, and recycle these powders to reduce production costs.

4. Pharmaceutical industry: A large amount of pharmaceutical dust will be generated in the pharmaceutical process, which will affect the quality of the medicine and the health of the workers. Cartridge dust collectors can efficiently filter and collect pharmaceutical dust to ensure the cleanliness of the pharmaceutical environment.

5. Cement industry: A large amount of cement dust is generated during cement production. Cartridge dust collectors can effectively collect and treat these dusts, reduce emission concentrations, and meet environmental protection requirements.

5. Cement industry: A large amount of cement dust is generated during cement production. Cartridge dust collectors can effectively collect and treat these dusts, reduce emission concentrations, and meet environmental protection requirements.

6. Steel industry: A large amount of dust and smoke are generated during the smelting and rolling of steel. Cartridge dust collectors can treat these pollutants, reduce pollution to the environment, and recover valuable metal particles. 7. Power industry: In the process of thermal power generation, coal combustion produces a large amount of fly ash and other dust. Cartridge dust collectors collect and treat these dusts to prevent environmental pollution and improve coal utilization efficiency.

In pulse jet dust collector, the filter cartridge can be arranged vertically, inclined or horizontally. Due to the effect of gravity, vertically arranged filter cartridges perform best when pulsed to remove dust from the surface of the filter cartridge. One side of the flower plate is the filter room, and the other side is the air box pulse blowing room, also called the clean air room

仕様