- 説明

- 問い合わせ

導入

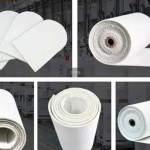

We provide Airslide belt for conveying bulk material by air gravity. The main use of Airslide belt is discharging, declining transportation or homogenizing the powder or small granular material in quiescent condition. Our airslide belt is named as Airslide fabric, Airslide membrane, Air slide cloth, Air slide canvas, Air permeable fabric, and Fluidization cloth, fluidising fabric, etc by our customer. We adopt 100% polyester for airslide fabric material.

PRODUCT CLASSIFICATION

Our POLYESTER fabrics can be used at temperatures between -60°C and +150°C. The airslide fabrics are made from polyester yarns.

We also have the Nomex, and basalt material, which can suitable for 240 and 450 degree temperature.

ADVANTAGES

- No moisture absorption

- No caking

- Resistant to rotting and decomposition

- Complete unloading without residues

- Consistent fluidization over the complete surface

- Good resistance to abrasion

- Low wear and therefore

- longer life

- Low shrinkage even when used under hot and humid conditions

WORKING PRINCIPLE

An Airslide belt is in the middle of a chute. Powder material will come into the chute above Airslide belt. Material will flow to the chute lower side as pneumatic blower down Airslide belt. That’s why we say Airslide belt can move powder material because of the wind power. And then, the rest wind will go out from the top of the chute. Through the moving, no parts moved except powder material. So that it can spare more energy and maintain cost, 等.

Our Airslide canvas is installed on the surface of the silo bottom. It is supplied for installation as aeration units on the sloped conical bottoms of bins and silos to aid in the withdrawal of dry relatively free-flowing material.

SPECIFICATION DATA

PACKING

We provide all kinds of standard export packing for cargo protection. The bag filter will be fixed on the container. The filter bag and cages will be fixed in corrugated box and steel framed structure.