Trasportatore a coclea

Bulk material transportation

The screw conveyor is a kind of equipment that drives the shafted screw conveyor or shaftless screw conveyor to rotate in one direction to push the material to move. It can transport materials horizontally, inclined or vertically. Tuttavia, the distance of conveying materials is limited. The conveying distance of a single screw conveyor is about 20 meters, but the screw conveyors work together with each other, thus increasing the conveying distance.

- Descrizione

- Inchiesta

INTRODUZIONE

Screw conveyors can transport materials horizontally, inclined or vertically. In terms of conveying form, it is divided into shafted screw conveyor and shaftless screw conveyor. In appearance, it is divided into U-type and tubular screw conveyor. The shaft screw conveyor is suitable for non-viscous dry powder materials and small granular materials. (Per esempio: cemento, fly ash, lime, grain, ecc.). Shaftless screw conveyors are suitable for conveying viscous and easily entangled materials. (Per esempio: sludge, household waste, ecc.). There is a thrust bearing at the end of the screw shaft to bear the reaction force of the material to the screw shaft. When the conveyor is long, the intermediate hanging bearing should be added.

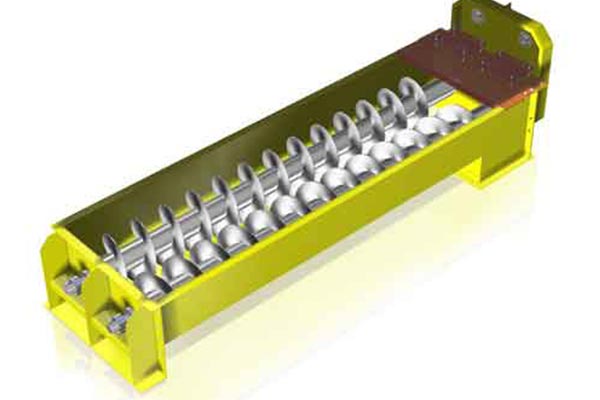

SHAFT & SHAFTLESS SCREW CONVEYOR

The single shaft, double shaft and multi shaft screw conveyor:

Advantages of the shaft screw:

1. Rotate with the shaft as the center and bear the moment, the spiral rotates smoothly without trembling.

2. Hanging bearings can be added to the shaft to extend the conveying distance.

3. There is no contact between the spiral blade and the shell to avoid mutual friction.

Disadvantages of shaft screw conveyor (relative to shaftless one):

1. Unable to convey viscous materials.

2. There are more matching parts and more maintenance work is required.

The shaftless screw conveyor

Advantages of shaftless screw conveyor:

1. It can transport materials that cannot be transported by shaft screw conveyors, such as: wet and pasty materials, semi-fluid and viscous materials, easily entangled and easily blocked materials, ecc.

2. It can run at low speed, drive smoothly and reduce energy consumption. The product has a large torque force and a large conveying volume.

Product disadvantage:

1. The blades are easily damaged. Since there is no intermediate shaft, all the force points are on the blade, so the thickness of the blade has a very important influence on the actual use of the equipment. Choosing an appropriate thickness of the helical blade directly affects the use effect.

2. The blade and the bottom lining plate rotate in contact and are easy to wear.

U TYPE & O TYPE SCREW CONVEYOR

Advantages of U-shaped screw conveyor:

1. The hanging bearing can be lubricated without removing the cover.

2. The cover is easy to disassemble when maintenance is required.

3. It can adapt to the inclined material conveying with an angle of less than 30 gradi.

Advantages of U-shaped screw conveyor:

1. The hanging bearing can be lubricated without removing the cover.

2. The cover is easy to disassemble when maintenance is required.

3. It can adapt to the inclined material conveying with an angle of less than 30 gradi.

U TYPE SCREW CONVEYOR SPECIFICATION

O TYPE SCREW CONVEYOR SPECIFICATION

SHAFTLESS TYPE SCREW CONVEYOR SPECIFICATION